Manufacturing metrics such as financial outcomes based upon factory output are critical for smart factories and growing companies. From managers up to the C-Suite, key decision-makers rely on up-to-date data to make informed decisions that can improve the bottom line. These leaders can move quickly, and change the direction of a factory, business unit, or even the entire company.

But, are you missing an opportunity to change faster? If you’re not sharing manufacturing metrics with your entire organization, you may be.

Displaying Real-Time Data in Factories

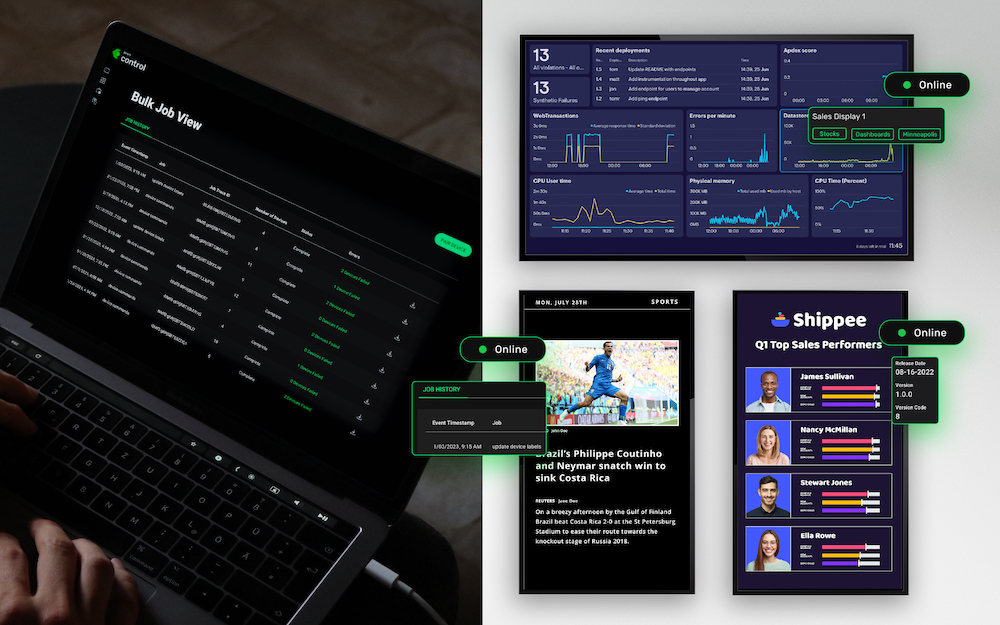

You may be thinking to yourself, “how can I share real-time data with all of my employees when they aren’t often (or ever) in front of a computer?”. There are a number of ways you can do that, but possibly the easiest way is to display your KPI dashboards on digital signage.

Imagine your employees, checking in for the day and reviewing the facility’s or their own specific line’s KPIs. Are they on track for the week, month, or quarter? Do they have ground to make up? It’s likely that, after bringing your manufacturing metrics to your employees, they’ll bring you great ideas for improving outputs and outcomes. After all, no one knows their own job better than the employee herself. She’s also the most likely to know what part of the job unnecessarily takes the most time or yields the best results.

It isn’t limited to just output and financial data, however. Manufacturing metrics such as safety goals and trends can help your employees understand where there may be issues bubbling to the surface.

Three Keys to Sharing Manufacturing Metrics

There are three keys to sharing your manufacturing metrics with your full employee base, in order to drive the most employee engagement and action.

Key 1: Share metrics that matter

Each employee base has a set of KPIs they are working towards. Be sure to share the metrics that align with those KPIs with those employees specifically. For example, if one of your factory maintenance KPIs is the mean time between failures, you will want to develop a dashboard and display it in key areas where the maintenance team will be able to see and digest the information. That same dashboard may not spur action with your welding team or sales team. Creating a map of your facilities and where your screens are located will help you identify which manufacturing metrics to show where and when.

Key 2: Use metrics to tell a story

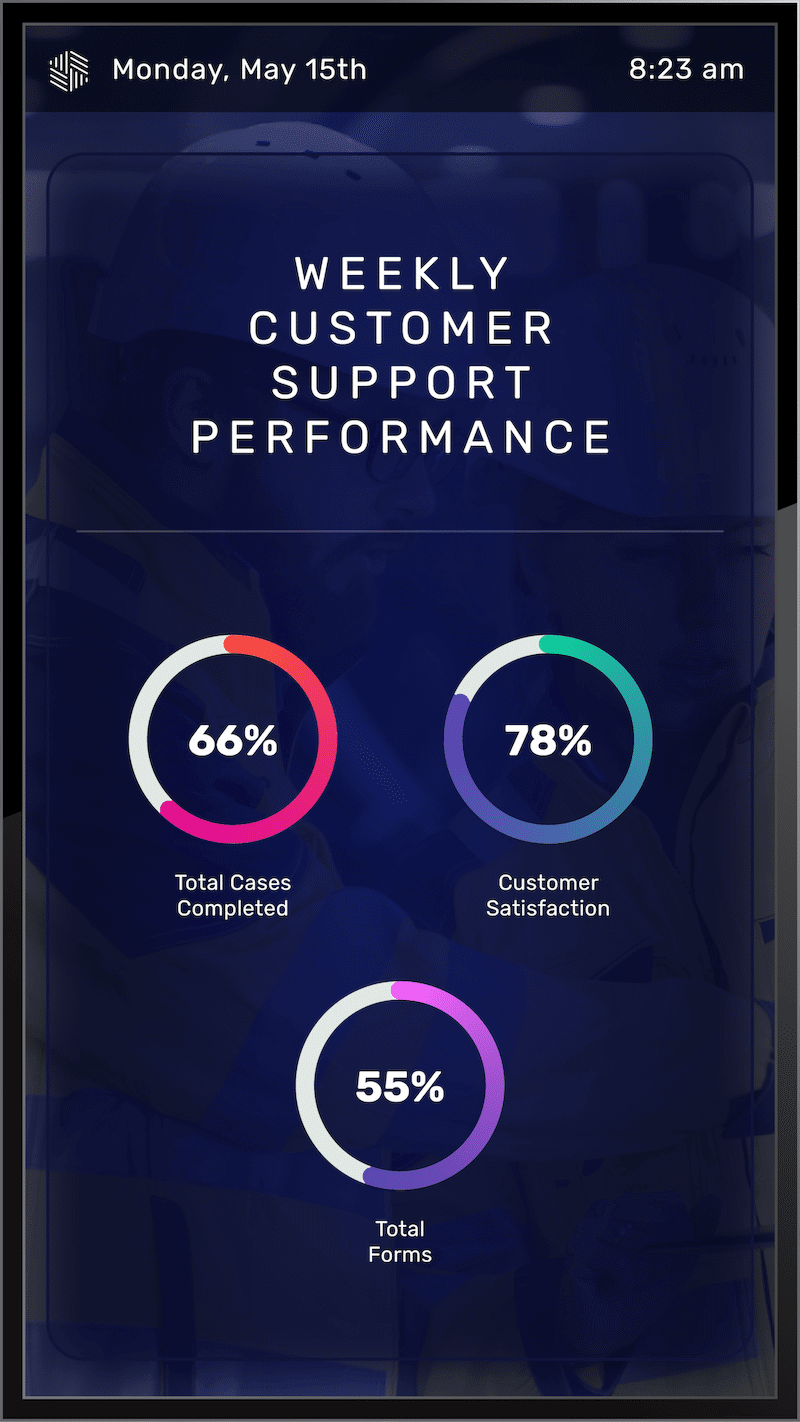

Visuals are critical to driving action. Simply sharing data points will leave the door open for misinterpretation. Manufacturing dashboards, when developed with the help of data visualization tools, can make complex data simple and truly drive action.

When dashboards include trend lines and goal comparisons, your employees can see quickly if they are improving or not and if they are meeting, exceeding, or missing their goals. As real-time data feeds into these dashboards, they can track progress and make adjustments, as needed. You can also see clearly how each line, facility, team, or business unit is performing against stated goals.

Key 3: Display metrics where they will be seen

Every facility has common areas where employees gather. Some common areas might include entry areas, near-time clocks, and break rooms. These areas are great places to display content – including manufacturing metrics.

Any time you can display metrics that matter in locations where employees are spending time, you can guarantee they will review that data.

What’s even better is when your dashboards and metrics spur conversations and brainstorm on how to improve outcomes. That said, don’t overlook areas in and around factory lines, sales floors, and other places your employees work. You will want to be specific about which content you show in less-traveled areas to ensure it resonates with employees in those areas.

Measuring Against Manufacturing Metrics Matters

You’ve invested in the tools to track, measure, and visualize key data from your manufacturing operation. And, you’ve likely set a cadence for sharing that data with key members of your team. Now is the time to think about how you share your manufacturing metrics with all your employees, across all of your offices, factories, and other facilities.

Sharing the data and building a culture that embraces data-driven decisions at all levels can improve your short- and long-term outcomes for your operation.